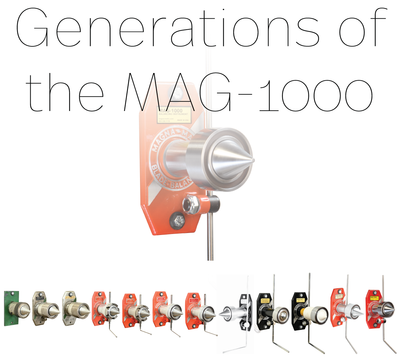

MAG-1000 Lawn Mower Blade Balancer Model Generations

Posted by Gerd F. Bauer II on Jan 19th 2022

In this article we will provide you with the information to be able to roughly date when your Magna-Matic MAG-1000 Blade Balancer was manufactured.

Magna-Matic invented the first rotary lawn mower blade balancer in 1958 in Port Washington Wisconsin. The inventor's name was Alvin J. Karrels. In the 1940's Alvin was a Ferguson tractor dealer, and in the 1950's he began selling and servicing lawn mowers brands like RED TIP, SACHS, and GRAVELY. He recognized very quickly that engine warranty issues on push rotary mowers were being cause by out-of-balance lawn mower blades. Alvin was awarded the the US PATENT and began manufacturing the MAGNA-MATIC BLADE BALANCER. At that time Magna-Matic was a division of the AJ KARRELS COMPANY. You will notice that balancers made from the 1950's up until the late 1980's carry name plates that read MAGNA-MATIC DIVISION - A.J. KARRELS CO - PORT WASHINGTON WIS USA - PATENT # LISTED.

Prototypes, cira 1954 - 1958

The first image (green bracket) is of an early home-made prototype of the blade balancer made by AJ Karrels, we do not have an exact date of this unit but estimate it is from the mid-1950's. These next two images are of prototypes that were built in acquiring the US Patents for the Magna-Matic blade balancer.

|

|

|

Generation 1, cira 1958 - 1963

This image is of the earliest production model of the MAGNA-MATIC BLADE BALANCER. The primary things to notice are that sleeve the cone is attached to is brass. So if you pull your magnet slide forward you will see the brass sleeve. The shell that the magnet is attached to is aluminum, and it has a chamfer at the end along with a step down behind the magnet. This version features an ALNICO magnet along with an aluminum rear magnet cap. The early wall mount cast bracket is a sand casting - you can tell if it is a sand casting because the whole back of the casting is flat without any cavities. The name plate is aluminum painted red with silver text, and it is riveted to the casting. The wall bracket will be painted orange, and the back of the casting will be silver (unpainted).

|

|

Generation 2, circa 1964 - 1967

The primary change to this version was that the sleeve (slide) was changed to steel - the brass design was no longer used. The magnet shell no longer has the step down cut. At this time the wall bracket was made as as a permanent mold. The way you can tell the difference between a sand casting versus a permanent mold is the sand casting will have a smooth back it will be all solid. The permanent mold has cavities behind the hub and the guage rod mount. The earlier permanent molds had the cavity behind the gauge rod mount is rectangular in shape.

Generation 3, circa 1968 - 1988

The magnet changes from the notched ALNICO magnet to a magnet designed by AJ Karrels incorporating a magnet sandwiched between two steel rings that were laminated to the aluminum magnet shell. These units still have an aluminum cap on the rear of the magnet. When looking at the back (wall-side) of the casting if the cavity behind the guage rod now is a circle. There is a slight change in the font cast into the wall bracket. The front also changes on the aluminum name plate.

Generation 4, circa 1988 - 1990

The aluminum bracket is now powder coated orange, so now the rear of the casting is now orange. The name plates on the balancer are no longer riveted but an aluminum decal. The decal is still red with silver text which reads: MAGNA-MATIC - PORT WASHINGTON WI 53074 USA - PHONE 414-284-5345 - PATENT # LISTED. A new logo with a spinning mower blade is on this adhesive aluminum label. It is at this time when Alvin J. Karrels sells Magna-Matic to his son-in-law Gerd F. Bauer. A German immigrant and mechanical engineer, Gerd has many other product ideas and therefore gives the Magna-Matic Blade Balancer its first model number. The MAG-1000 Blade Balancer. Please note it is during this time the rear magnet aluminum cap is discontinued even though it is pictured below.

Generation 5, circa 1991 - 1996

The gauge rod for checking blade straightness goes from the telescoping design to a fixed steel rod that is chrome plated with a ball nose end. The gauge rod slides through a spring loaded (white plastic) bushing design. The balancer bracket is now powder coated black rather than orange. Due to this change the back of the wall bracket is no longer silver or the color of raw aluminum. The aluminum name plate is changed to gold with a black boarder and black text reading: MAGNA-MATIC CORP - WALDO WI 53093 USA - 1-800-328-1110 PHONE - PATENT # LISTED.

The MAG-500 and MAG-600 models, circa 1991 - 1996

During the 1990's Magna-Matic designs and patents two new styles of balancer the MAG-500 spring-loaded ball type and the MAG-600 spring-loaded plastic cone type balancer. The MAG-500 is pictured on the left, and the MAG-600 on the right. These two models were initially designed for foreign market they were also sold in the USA.

|

|

Generation 6, circa 1996 - 2012

Since generation 3 the magnet was made up of two metal rings and the magnet material - laminated to the shell. Now the inner ring is removed - and the magnet is laminated directly to the shell. The magnet is increased in size and now has a magnet pull strength of 120 lbs. The magnet sleeve gets the step down like the generation one version. The adhesive aluminum nameplate gets a black border. The gauge rod is now made of stainless steel. The aluminum cast wall bracket is now powder coated red. Other machining accuracy is improved.

Generation 7, circa 2012- 2019

The gauge rod bushing and stud are now made from black Delrin rather than white Delrin. The name plate becomes a yellow vinyl decal with a black border. Machining accuracy is further improved.

Generation 8, circa 2019 - Present

The yellow vinyl name plate decal loses its black border and accuracy specs are listed on the MAG-1000. In 2021 the rear of the wall bracket gets a silver decal with the year of manufacture printed on it. The gauge rod gets a point machined on the tip rather than the previous ball nose end.

If you have a MAGNA-MATIC Blade Balancer of any age - we still will service all previous generations. The only limitation of repair is if you do have a balancer that has the notched style ALNICO magnet - and the magnet is broken or cracked. We no longer have any stock of the ALNICO magnets, and they are now very expensive.

If you have a balancer that requires repair - fill out our service form here.